You have no items in your shopping cart.

Air Spring Upgrades

For the last 10 years or so we've had suspension companies pushing air springs onto us, phasing out our excellent performing coil springs with such rhetoric as "coil like performance". There are upsides to air-springs: they're infinitely adjustable and very light. But there are some downsides too and it takes a huge amount of engineering brain smoke to make them behave in an acceptable way.

For the last 10 years or so we've had suspension companies pushing air springs onto us, phasing out our excellent performing coil springs with such rhetoric as "coil like performance". There are upsides to air-springs: they're infinitely adjustable and very light. But there are some downsides too and it takes a huge amount of engineering brain smoke to make them behave in an acceptable way.

The claims of "coil like performance" - that's pure bollocks

See, a coil spring is almost completely linear. If the spring is 45 lb/in (that's pounds per inch) then for the first inch of travel it will take 45 pounds weight to compress it. Add another 45 pounds and it'll compress another inch. Simple.

Coil springs are simple, reliable, consistent and excellent for performance, giving great small bump response, excellent mid stroke support and predictable full stroke.

Air springs in comparison (yes I'm generalising) have a high starting force, weak mid-stroke and too firm end-stroke. To combat this, a negative spring is used; sometimes coil, sometimes air. The negative spring offsets the force of the main air spring to bring it closer to zero force at full extension.

Enough of the generalising - let's get specific

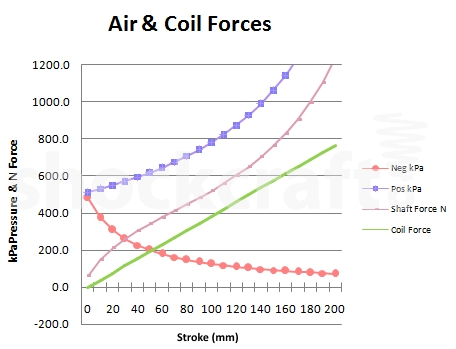

Here's a pretty graph (top right) I've generated from a very common air fork. It is showing the effect of positive (purple) and negative (blue), both individually and together. The end result (pink) is getting close to a straight line. The green line is from a 45 lb/in coil spring.In this graph below the coil & air spring look pretty similar; slopes about the same in the middle, with the air spring firmer at the start and end.

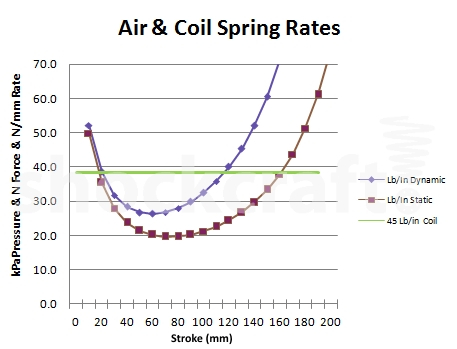

But lets look what happens when we differentiate the two to find the actual spring rates! This is where our air springs start to look a bit funky. The Green line in the graph at bottom right is the completely consistent coil spring. The brown is what you get if you slowly compress an air spring and the blue is a rapidly compressed air spring (air builds heat and more pressure when compressed fast).

So the air spring is about 20% firmer over small bumps (where you don't want it) but is almost half the firmness in the midstroke where you need support (like riding slowly down technical tracks). At the end the air spring ramps up quickly.

So it's harsh over small stuff, blows through the travel too quickly and is hard to get full travel.

So what can you do to improve it?

Well we have some tricks which work on different parts.Improving Start of Stroke

To greatly improve the start of the stroke you can increase negative air volume. This flattens out the start of the stroke, reducing the initial spring rate, which lets you run more pressure to firm up the mid-stroke.Aftermarket options to increase negative volume:

• Vorsprung Luftkappe (shown at right)

• Shockcraft Hot Rod (not yet released to the public)

These two will both fit and work together in some forks.

So that's the initial and mid-stroke. But what about mid-end?

Improving Mid-End Stroke

The only way to firm up the mid-stroke without making the end-stroke worse is by creating another air chamber. There are two ways to do this: with transient air pressure or with a second sealed and pressurised chamber with piston.

Creating another chamber causes the now intermediate chamber to ramp up in pressure sooner to give a firmer and more supportive mid-stroke. At deeper stroke this either blows-off into the second positive chamber or starts to activate the second piston and chamber. Aftermarket options to improve mid to end stroke:

Aftermarket options to improve mid to end stroke:

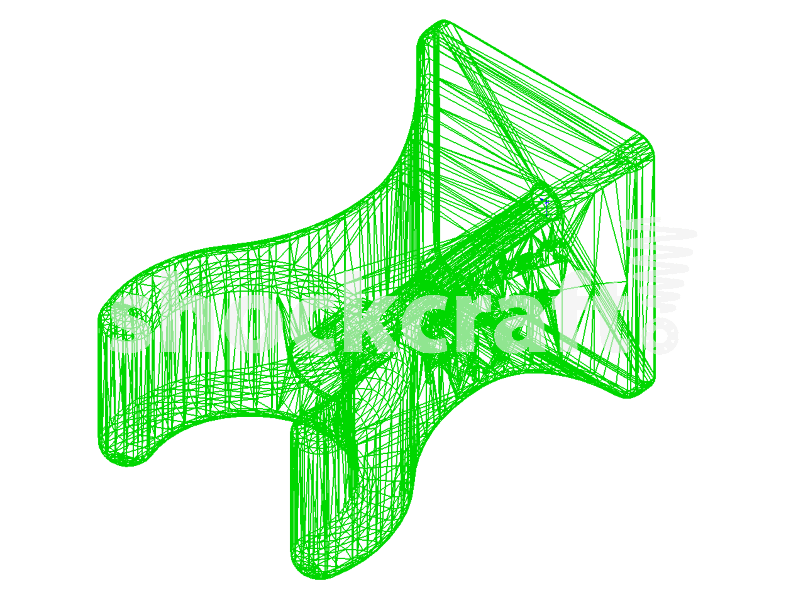

• SD Components Dynamic Volume Chamber (SD-DVC) (shown at left)

• MRP Ramp Control

• Manitou Inifinite Rate Travel (IRT)

• Ohlins Triple Chamber

The MRP Ramp Control is one that blows off into a second chamber and needs the fork to fully extend to reset.

The Manitou IRT, SD-DVC and Ohlins are two chamber systems with two air valves for tuning.

Tuning Differences

If you run a Luftkappe it increases negative volume by reducing positive. On RockShox forks it is recommended to start with one less token than you previously ran. Use our standard natural frequency method to set air pressure.

The Shockcraft Hot Rod does not change positive chamber volume on Pike/Lyrik forks, but it does on others (like Boxxers). Regardless, it changes the spring balance so pressures will need reset based on natural frequency.

The SD-DVC and Manitou IRT are more difficult to tune as they introduce not only a second chamber with pressure difference, but they introduce completely new tuning options:

• For trail riding with expected sharp but moderate sized bumps I recommend your normal air pressure +10psi in the top chamber and normal air pressure -10psi in the bottom chamber.

• For more aggressive riding wanting more bottom out control you can run up to double the pressure in the top chamber.

You can also vent the top chamber and just run the bottom to disable the effect in SD-DVC and Manitou IRT. This makes them behave like a conventional single air chamber.

The MRP Ramp Control is a blow-off threshold between the two chambers which is controlled by the dial on the top. Set your normal pressure by natural frequency, wind the knob fully open (anti-clockwise) and increment it up until you're happy with the support. Too far will make the mid-stroke too harsh. Not enough will give no benefit.