You have no items in your shopping cart.

High Flow Pistons & Oil Flow

In your suspension (fork and shock) there is an oil damper. The damper controls the speed and motion of the suspension and it completely makes or ruins the ride. A lot of stock suspension has a damper tune that simply don't work well so there is a thriving industry offering solutions; some good, some rubbish.

Currently there's a lot of buzz about upgrading pistons - High Flow Pistons to be precise. But there's also a lot of outright bollocks, so we're here to tell you how this works (or doesn't).

Suspension relies totally on oil flow. It slows down oil flow to control fork motion but also lets a lot of oil flow quickly to deal with sharp bumps and hard landings. Oil flow is controlled by shims and ports on pistons.

The piston's job is to direct oil to the right shims in the right direction. Almost all are bi-directional, they flow both ways, but usually run lots of damping in one direction and minimal damping in the other with a check-shim to let oil out easily.

There are good pistons and not-so-good pistons.

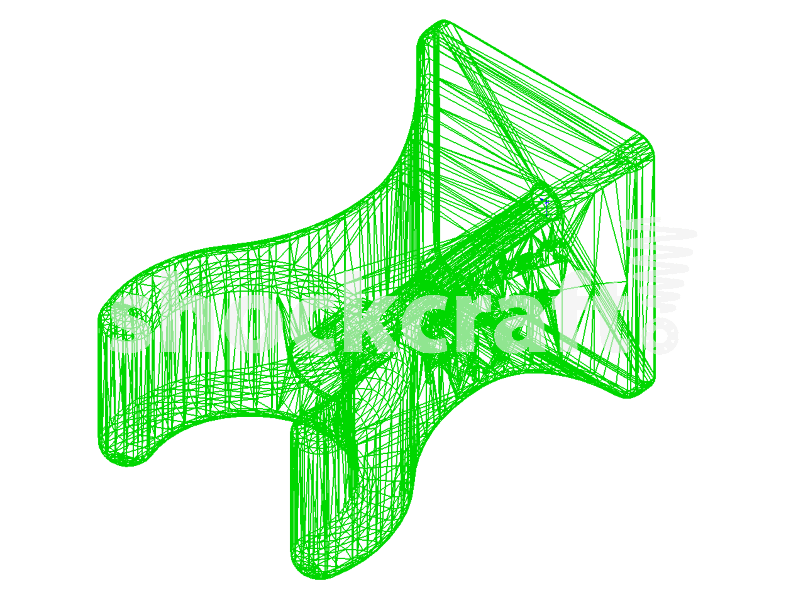

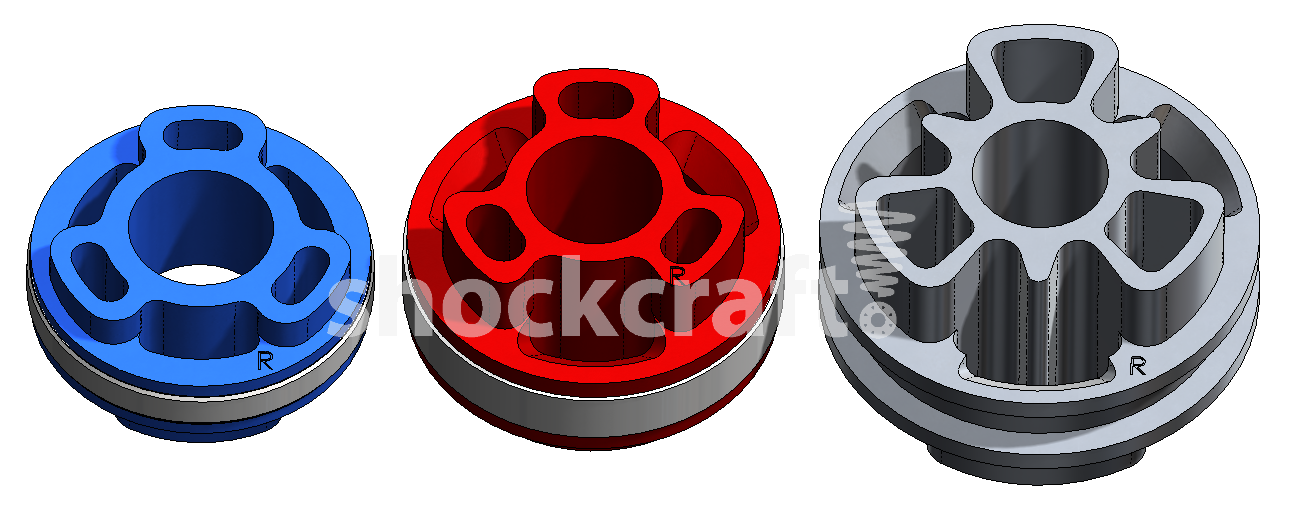

Here is a lineup of well designed OEM fork pistons and on the right is one fully assembled:

These pistons are all 3-port type; 3 large ports sending oil to shims on compression (flow out underneath) and 3 smaller ports sending oil to shims on rebound out the top. These three are all "high flow" type and well suited for rebound/mid-valve damping duties in a fork.

Yet despite excellent piston design, some forks are still horrible performers. They spike on fast hits and sharp edges, running rough and sending harshness through to the rider.

The cause of the harshness isn't the piston. The oil simply cannot get to and from the piston fast enough for a high flow piston to work; like having a huge shower head fed by a tiny pipe. The suspension instead of absorbing sharp bumps will hit internal oil flow restrictions and kick those bumps straight through to the rider. These force spikes are most noticable on square edged bumps and at higher speeds.

Despite the pistons not being the problem, some suspension companies still sell aftermarket “High Flow” pistons for these forks; pistons which cost a lot of money, yet make absolutely no difference to performance. Further, some of these aftermarket pistons are two port designs which flow worse than the factory items! It's like buying another big shower head (with fewer holes) and expecting it to solve your pipe problems.

So What's the Solution?

In the shower head example above. We make sure your pipes match the shower head. To fix harshness and spiking we have a set of engineered modifications we call “unharsh”. We find and fix all the oil flow problems so the only bottle-neck is the carefully chosen damping valves and not the oil paths to and from them. Our best known "unharsh" treatment is for Rockshox Charger dampers in Pike, Lyrik and Boxxer forks. We also have solutions for many more but these solutions take a lot of time to analyse, test, prototype and prove.

Who Needs An Aftermarket High-flow Piston?

Who Needs An Aftermarket High-flow Piston?

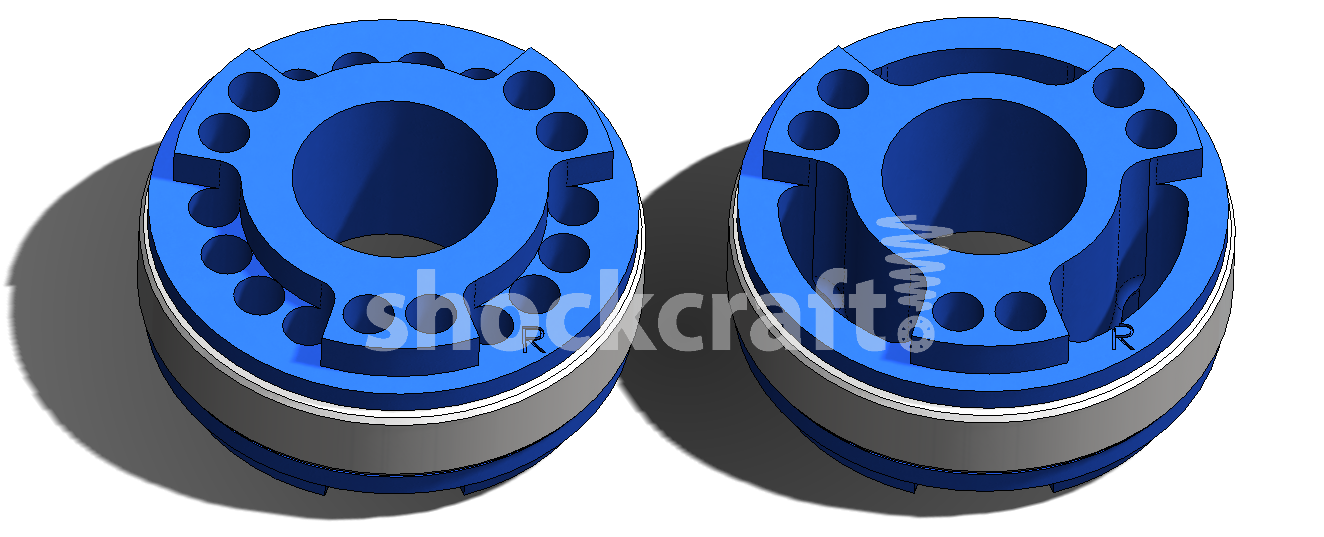

Some forks come with pistons that flow well but with simple modifications can perform even better at very high compression speeds. The Manitou cartridge dampers used in the Dorado, Mattoc, Magnum, Mastodon, Minute/Marvel all fit into this category. At right is an example of a Manitou original piston, with the high flow modified version at far right. The High Flow modifications change class-leading forks into ones that deliver super-powers. It enables them to move at compression speeds that simply eat rocks at speed while staying stable and composed.

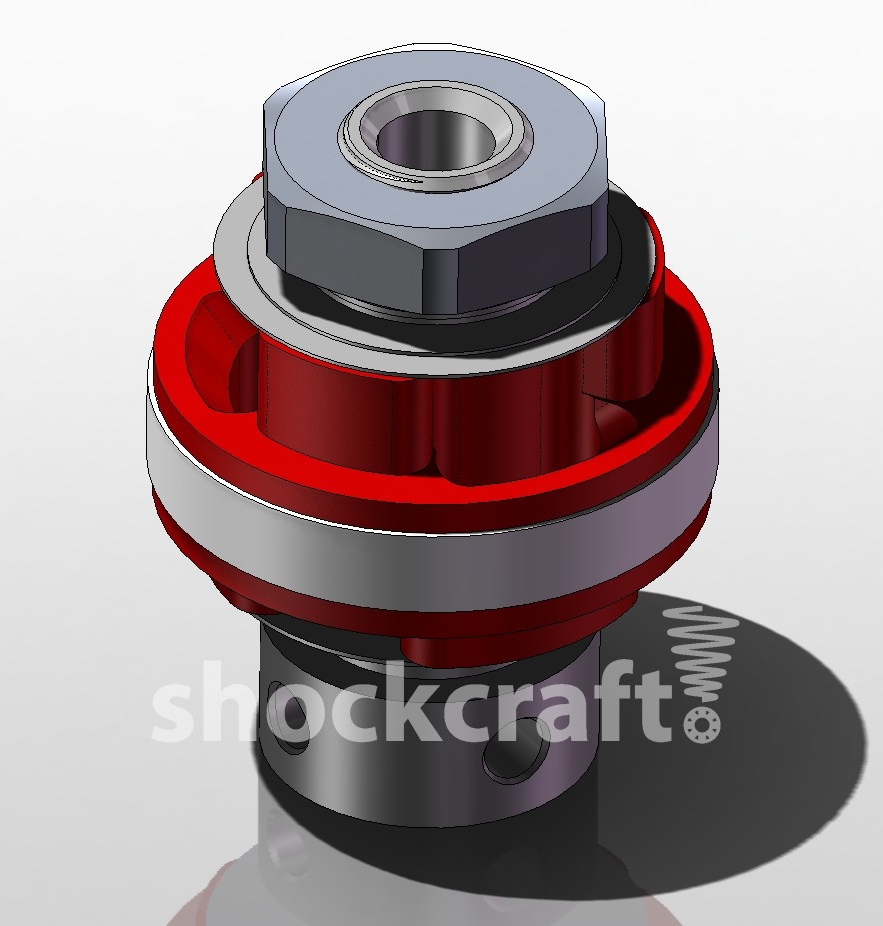

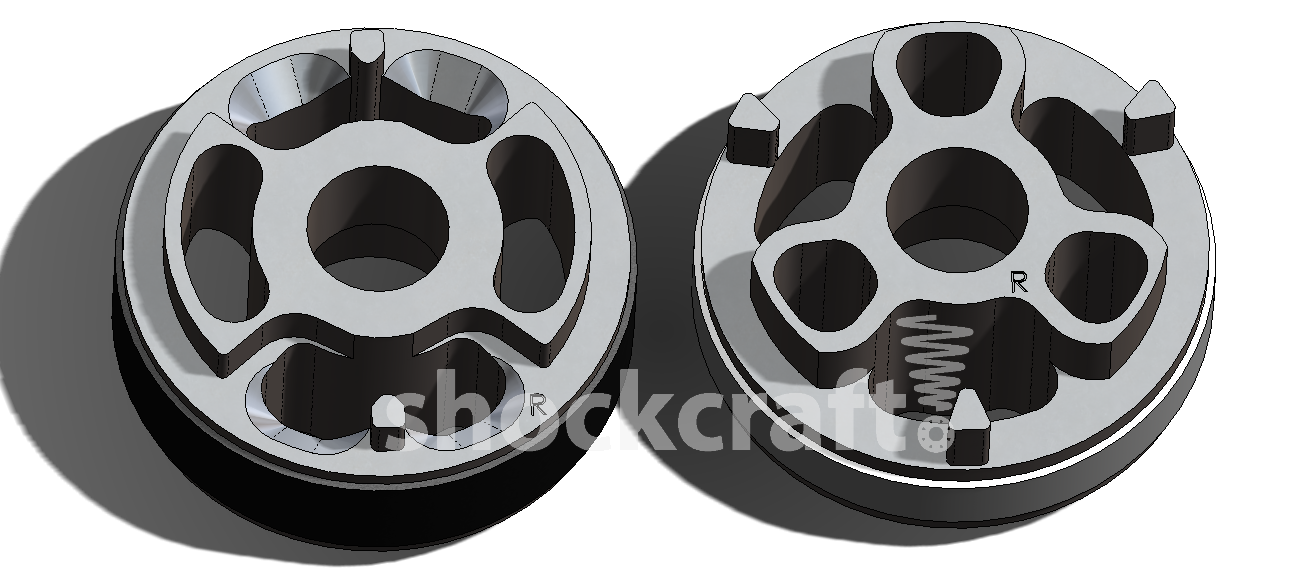

Then we have some forks containing pistons with unbelievably bad oil flow, especially pistons with only 2 ports. The only real solution is engineering; calculating, designing and manufacturing a replacement piston in-house. While the piston below left looks like it has decent size ports and big chamfers to get oil in and out, it chokes and simply cannot deliver enough flow to the shims via 2 ports. The piston on the right cuts the unwanted compression forces in half, eliminating spiking and providing a massive difference in fork performance. Below right is the high flow piston being manufactured (in-house). This High Flow Piston is available as part of our new Full Works Tune for the Ohlins RXF36 forks.

Conclusion

Every damper setup is different and has different issues. There is no “one-type-fits-all” upgrade that will work well and many aftermarket bolt-ins don't deliver. To acheive good performance requires in-depth analysis of the problems and careful design of solutions that will work.

Our first whole damper analyse, fix and tune was targetted at at the Rockshox Charger dampers (Gen 1 RC & RCT3) used in Pikes, Lyrik and Boxxer. We called this “Unharsh” and packaged it with a Matrix Tune where, as well as fixing the oil flow problems, we provide a revalve suited to your riding style and terrain.

We are now extending this program out to:

Rockshox Charger 2 damper (Pike, Lyrik & Boxxer 2018+)Fox FIT4 and FIT-CTD is coming for all Fox cartridge dampers worth tuning (CTD-EVO is not in this list).

Our Highflow programme will be rolled out soon for:

Manitou Dorado, Mattoc, Magnum, Mastodon, Minute Pro & Marvel Pro.

Our Full Works Tune is now available for the Ohlins RXF36 fork.

Stay tuned.